Plastic member capacity of semi-compact steel sections

Scientific insights evolve over time and the topic of the design resistance of class 3 steel cross-sections is no exception to that. In Eurocode 3 “Design of steel structures”, it is assumed they transfer no more than an elastic level of resistance, even though today we recognize that an internal plastic redistribution may, sometimes significantly, increase their capacity to resist forces. Time for an update in the second generation of Eurocodes.

SEMI-COMP & SEMI-COMP+ research projects

The outcome of two research projects funded by the European Research Fund for Coal and Steel (RFCS) produced a more economic design method for class 3 steel cross-sections:

- SEMI-COMP “Plastic member capacity of semi-compact steel sections – a more economic design” (RFSR-CT-2004-00044)

- SEMI-COMP+ “Valorisation action of plastic member capacity of semi-compact steel sections – a more economic design” (RFS2-CT-2010-00023)

Prior to the findings in both research projects, class 3 cross-sections could only rely on their elastic resistance properties. The newly suggested approach allows plastic resistance properties to a certain degree - a kind of elasto-plastic resistance capacity which is higher than merely relying on elastic properties. The conclusion? The steel material can be used in a more economical way. A win-win situation.

The first research project was completed in 2008 after three years of research. The outcome was a calculation model that is fully in line with the Eurocode 3 principles and at the same time allows for an increase of the design resistance of class 3 profiles. This was validated through numerical and experimental testing.

The second research project was intended to disseminate to professionals the newly developed design procedure through design guidelines, specific software named “Semi-Comp Design” and seminars. More information about these guidelines can be found on the following website: https://www.tugraz.at/en/institutes/lki/research/projects/

Inclusion of SEMI-COMP+ findings in the next generation of EN 1993-1-1

The design of semi-compact sections will be included in the next generation of EN 1993-1-1 and it supports the same approach as proposed via the SEMI-COMP+ findings. In the final draft, it is located under Annex B. The design of semi-compact sections in the draft version of the next generation of EN 1993-1-1 supports the following profile types:

- I- or H-sections (rolled or welded)

- RHS or doubly symmetric welded box sections

- Circular or elliptical hollow sections

SEMI-COMP+ design approach

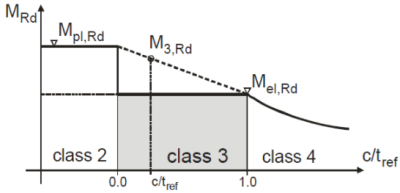

As indicated before, this approach provides elasto-plastic design resistances for class 3 profiles. It can be interpreted as a linear interpolation between the plastic and elastic resistances which is illustrated below by the dashed lines:

If the dashed line is left out in the current approach, a class 3 has a huge drop in bending resistance for class 3 profiles as it transitions abruptly from plastic to elastic resistances. Thanks to the dashed line (elasto-plastic) bigger resistances for class 3 profiles are obtained because of the linear transition between the plastic and elastic domain.

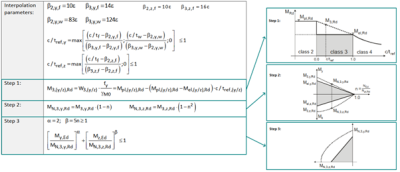

I or H-sections

Table 13 of the SEMI-COMP+ publication offers a straightforward method to determine the elasto-plastic design values for class 3 I or H-sections:

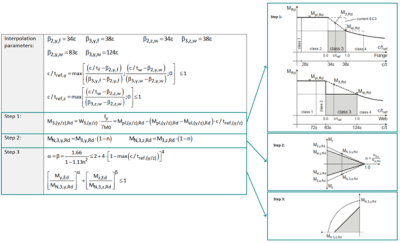

RHS-sections

Table 14 of the SEMI-COMP+ publication offers a straightforward method to determine the elasto-plastic design values for class 3 RHS-sections:

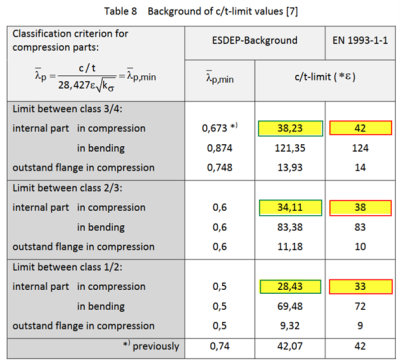

Modified classification limits

The SEMI-COMP+ research project revealed that the classification limits in the current EN 1993-1-1 don’t meet the specified safety level in accordance with ESDEP (European Steel Design Program). The modifications are used in SCIA Engineer as specified in: https://help.scia.net/webhelplatest/en/#steel/code_checks_inc_fire_resistance/tb_steel_uls/en/classification_modified_classification_limitis_semi_comp.htm

The modification is mentioned under Table 8 of the SEMI-COMP+ publication as can be seen below:

Implementation in SCIA Engineer

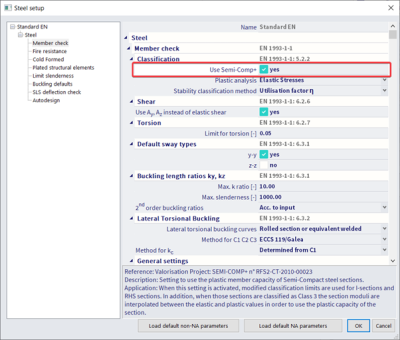

SCIA Engineer implemented the more economic design method according to SEMI-COMP+ ever since version 17. It is by default activated and thereby providing the more economical solution. The setting is located in the steel setup where it can be activated or deactivated:

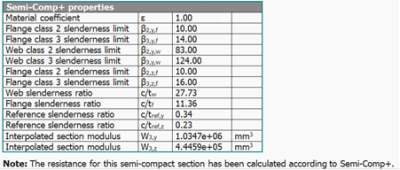

When it is activated and in case the cross-section is classified as class 3 and as a type I-/H-section or RHS section, the SEMI-COMP+ approach is used as is illustrated below for an example using an HE300AA profile:

The interpolated section moduli W3,y and W3,z are interpolated values between the elastic and plastic section modulus. The c/tref-values indicate which side the interpolated values are closer to. A c/tref-value closer to 0 signifies an interpolated section modulus closer to the plastic section modulus, while a c/tref-value closer to 1 signifies an interpolated section modulus closer to the elastic section modulus.

More information about the implementation in SCIA Engineer can be found here: https://help.scia.net/webhelplatest/en/#steel/code_checks_inc_fire_resistance/tb_steel_uls/en/semi-comp+.htm

Sources:

Valorisation Project Semi-Comp+, N° RFS2-CT-2010-00023, Background Information, 22 march 2012

prEN 1993-1-1:2020 (annex B)